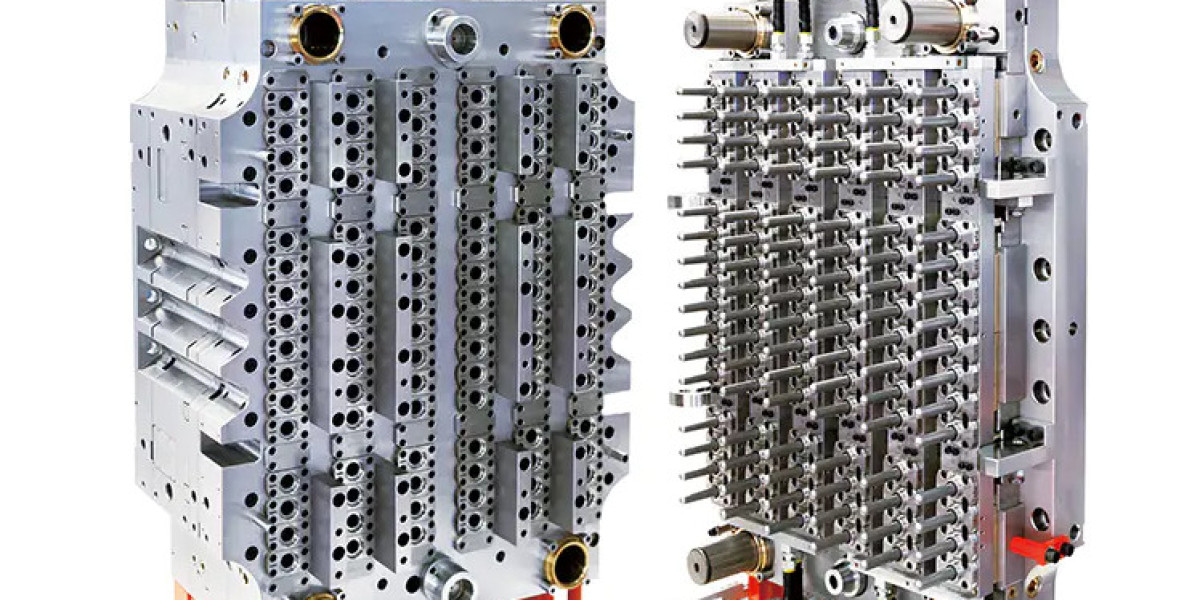

A Preform mold plays a vital role in the production of plastic bottles and containers, forming the initial shape before the final blowing process. The design and precision of a Preform mold directly affect the quality and consistency of the final product. Each mold must handle high temperatures and pressures while maintaining dimensional accuracy to produce uniform preforms that meet industrial standards.

The primary function of a Preform mold is to shape heated plastic into a compact, solid form that can later be expanded into a container. Injection molding is the most commonly used method, where molten polymer is injected into the mold cavity. The mold must provide uniform cooling to prevent warping, shrinkage, or surface defects. Proper thermal management ensures that preforms retain consistent weight, thickness, and clarity.

Material selection for Preform molds is critical to ensure durability and performance. Mold steel and other wear-resistant alloys are frequently used due to their ability to withstand repeated thermal cycles. Surface treatment, such as polishing or coating, enhances mold life and reduces friction during injection. These considerations reduce maintenance frequency and improve overall production efficiency.

Design considerations go beyond strength and durability. The geometry of the mold cavity influences the wall thickness distribution of the preform. Uneven distribution can lead to weak points in the final bottle, affecting structural integrity and resistance to pressure. Engineers often use simulation tools to analyze mold flow, optimizing cavity shapes and runner systems before manufacturing.

The versatility of Preform molds allows them to be used for different bottle sizes and neck finishes. Some molds are modular, enabling manufacturers to change cavities or neck components without producing a completely new mold. This flexibility supports a range of container volumes, from small bottles to larger containers, while maintaining production speed.

Cooling systems play a key role in Preform mold operation. Water channels or other cooling mechanisms help remove heat efficiently, ensuring rapid solidification of the injected material. Effective cooling reduces cycle time, supports consistent production, and minimizes energy consumption. The combination of design, material, and cooling ensures reliable performance in high-volume operations.

Maintenance practices also affect the performance of Preform molds. Regular inspection of cavities, runners, and alignment surfaces prevents defects from developing. Polishing or minor repairs can extend mold life, reducing downtime and improving cost-efficiency. Preventive care ensures that molds continue to produce preforms that meet dimensional and aesthetic requirements.

Preform molds are essential for modern bottle manufacturing. They provide precision shaping, consistent quality, and adaptability to different container designs. Continuous improvement in mold design, material selection, and cooling technology allows manufacturers to meet changing production demands efficiently. The Preform mold remains a practical tool for producing uniform, high-quality preforms for a variety of applications.