Everything you need to know about professional storage rack installation in Dubai—from planning to certification

Proper installation of storage racks is critical for safety, efficiency, and regulatory compliance in Dubai's warehouse operations. Whether you're setting up a new facility in JAFZA, expanding operations in Dubai Industrial City, or upgrading existing infrastructure, understanding the installation process ensures your investment delivers optimal performance while meeting UAE building codes and safety standards.

This comprehensive guide covers every aspect of storage rack installation in Dubai, from initial planning through final certification and ongoing maintenance.

Why Professional Installation Matters

Safety and Structural Integrity

Improperly installed storage racks pose serious safety risks including collapse, product damage, and worker injuries. Professional installation ensures systems are correctly assembled, properly anchored, and safely configured according to engineering specifications and manufacturer requirements.

Critical Safety Factors:

- Proper foundation anchoring preventing tip-over

- Correct beam-to-upright connections with safety locks

- Accurate vertical alignment and plumb tolerances

- Appropriate load distribution and capacity compliance

- Professional inspection and certification

Dubai Regulatory Compliance

Dubai Municipality and Civil Defense regulations mandate specific installation standards for storage systems. Professional installation provides required documentation, certifications, and compliance assurance necessary for inspections and insurance coverage.

Required Approvals:

- Dubai Municipality building permits

- Civil Defense safety clearances

- Structural engineering certifications

- Professional installation documentation

- Insurance compliance verification

Long-Term Performance

Professional installation maximizes system lifespan, operational efficiency, and safety throughout the rack's service life. Proper techniques prevent premature wear, structural stress, and maintenance issues that compromise performance and increase long-term costs.

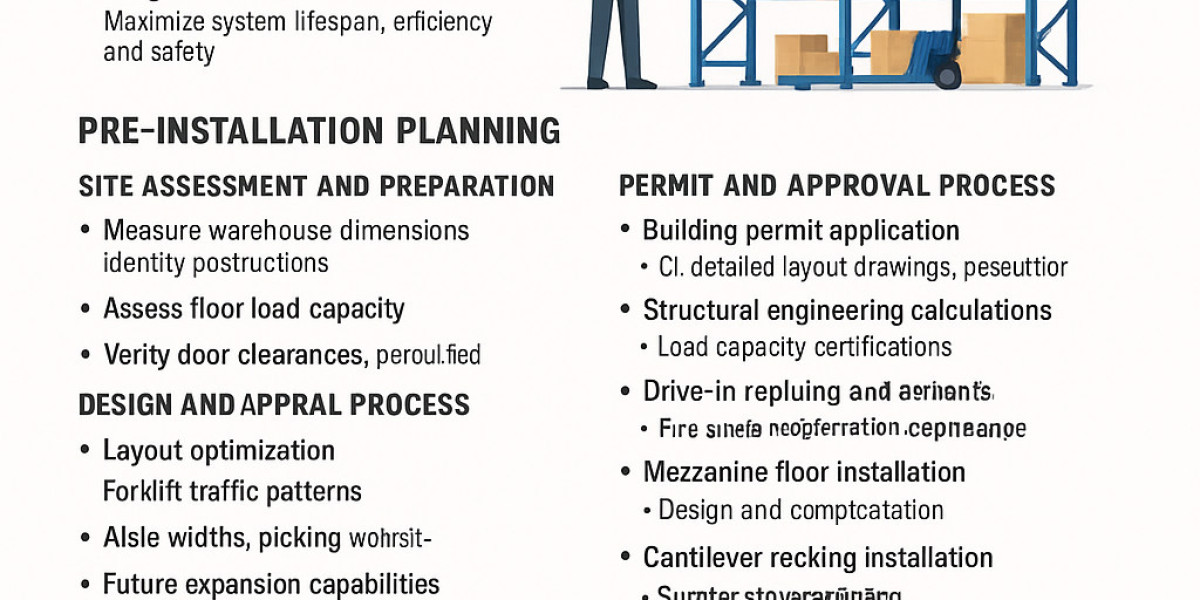

Pre-Installation Planning

Site Assessment and Preparation

Facility Evaluation:

- Measure exact warehouse dimensions including ceiling height

- Identify structural columns, utilities, and obstructions

- Assess floor load capacity and condition

- Verify door clearances for material delivery

- Document fire suppression system locations

Floor Requirements:

- Concrete flatness within 3mm per 3 meters

- Load-bearing capacity: Minimum 5,000 kg per sqm for heavy racks

- Surface levelness tolerances: ±5mm over 10 meters

- Crack repair and surface preparation

- Anchor point drilling preparation

Utility Clearances:

- Electrical conduits and lighting fixtures

- HVAC ducts and ventilation systems

- Fire sprinklers and suppression equipment

- Plumbing and drainage systems

- Security and surveillance equipment

Design and Engineering

Layout Optimization:

- Maximize storage density while maintaining accessibility

- Plan efficient forklift traffic patterns

- Ensure adequate aisle widths for equipment

- Account for picking and replenishment workflows

- Design for future expansion capabilities

Engineering Calculations:

- Load capacity analysis per beam level

- Foundation stress calculations

- Seismic load considerations (UAE seismic zone)

- Wind load factors for tall installations

- Safety factor compliance (typically 1.5-2.0x)

CAD Design Services: Professional suppliers like Easy Way Racks provide detailed layout drawings showing exact placement, dimensions, and specifications before installation begins.

Permit and Approval Process

Dubai Municipality Requirements:

- Building Permit Application

- Submit detailed layout drawings

- Provide structural engineering calculations

- Include load capacity certifications

- Specify anchoring methodology

- Timeline: 2-6 weeks typical

- Civil Defense Approval

- Demonstrate fire safety compliance

- Show sprinkler clearance maintenance

- Document emergency access routes

- Verify aisle width standards

- Timeline: 2-4 weeks

- Professional Engineering Stamp

- Required for systems over 6 meters height

- Load calculations by licensed engineer

- Seismic compliance certification

- Foundation adequacy assessment

- Cost: AED 3,000-15,000

Material Procurement and Logistics

Component Verification:

- Confirm all materials meet specifications

- Verify quantities against layout drawings

- Inspect for shipping damage

- Check component compatibility

- Ensure hardware completeness

Delivery Coordination:

- Schedule around warehouse operations

- Coordinate access through security checkpoints

- Arrange material storage areas

- Plan unloading equipment requirements

- Sequence deliveries for installation flow

Installation Process by Rack Type

Selective Pallet Racking Installation

Step 1: Foundation Preparation (Day 1)

- Mark exact column locations per layout drawings

- Drill anchor holes to specified depth (typically 100-150mm)

- Clean holes thoroughly removing all debris

- Insert expansion anchors or chemical anchors

- Allow chemical anchors to cure (24-48 hours if required)

Step 2: Upright Frame Installation (Days 2-3)

- Position base plates at marked locations

- Install and hand-tighten anchor bolts

- Erect upright frames with temporary bracing

- Check vertical plumb using laser levels (tolerance: ±3mm per 10m)

- Install horizontal and diagonal bracing

- Final tighten all anchor bolts to specification torque

Step 3: Beam Installation (Days 3-5)

- Install beams starting from bottom level

- Ensure beam connectors fully engage uprights

- Install all beam safety locks/clips

- Verify beam levelness across bay

- Check diagonal measurements for square alignment

- Work upward installing successive levels

Step 4: Accessories and Safety Features (Day 5-6)

- Install column protectors at aisle intersections

- Add row end protectors for corner safety

- Install wire mesh decking or pallet supports

- Add load capacity signage

- Install backstops if specified

- Apply high-visibility marking where required

Step 5: Final Inspection and Testing (Day 6-7)

- Complete dimensional verification

- Check all connections and safety devices

- Verify vertical and horizontal alignment

- Load test at specified percentages

- Document as-built conditions

- Obtain final inspection approval

Timeline: 5-7 days for 100-200 pallet positions

Heavy Duty Racking Installation

Heavy duty systems require enhanced installation procedures due to extreme loads and structural demands.

Enhanced Requirements:

- Reinforced floor anchoring (deeper/larger anchors)

- Additional base plate support (larger plates, more bolts)

- Stricter alignment tolerances (±2mm per 10m)

- Enhanced bracing requirements

- Mandatory load testing at 125% rated capacity

- Professional engineering certification required

Installation Modifications:

- Specialized heavy-duty installation tools

- Torque wrenches for precise bolt tightening

- Laser alignment systems for accuracy

- Additional safety bracing during installation

- More extensive foundation preparation

Timeline: 7-10 days for 100-150 positions

Drive-In Racking Installation

Special Considerations:

- Precise rail alignment critical for forklift operation

- Guide rail installation requires extreme accuracy

- Entry frame reinforcement essential

- Floor levelness more critical than selective racking

- Additional bracing for stability

Installation Sequence:

- Install rear support frames

- Erect upright frames with precise spacing

- Install horizontal load beams

- Add guide rails with exact alignment

- Install entry protection systems

- Verify forklift clearances throughout

Critical Measurements:

- Guide rail alignment: ±2mm over full length

- Pallet stop positioning: Exact per specifications

- Entry clearances: Minimum per forklift dimensions

- Vertical spacing: Precise for pallet stacking

Timeline: 6-9 days for 100-150 pallet positions

Mezzanine Floor Installation

Most complex installation requiring multiple trades and comprehensive engineering.

Phase 1: Structural Framework (Week 1-2)

- Install primary support columns

- Erect main beam structure

- Add secondary joists and supports

- Install cross-bracing systems

- Verify structural alignment throughout

Phase 2: Flooring Installation (Week 2-3)

- Install GI grating, steel plate, or wood panels

- Secure flooring to structural supports

- Ensure proper spacing and alignment

- Add edge protection and toe boards

- Seal joints and transitions

Phase 3: Access and Safety (Week 3-4)

- Install staircase structures

- Add safety railings and handrails

- Install gates and access controls

- Add lighting and electrical (if required)

- Apply non-slip coatings if specified

Phase 4: Integration and Testing (Week 4)

- Connect to building systems

- Install safety signage and load markings

- Conduct structural load testing

- Obtain engineering certification

- Complete final inspections

Timeline: 3-4 weeks for 200-500 sqm

Cantilever Racking Installation

Unique Installation Aspects:

- Heavier base structures requiring substantial anchoring

- Arm installation requiring precise leveling

- Load testing of cantilevered arms essential

- Special attention to lateral stability

- Bracing critical for seismic resistance

Installation Steps:

- Install heavy-duty base structures with reinforced anchoring

- Erect vertical columns with temporary support

- Install arms at specified heights and angles

- Add diagonal bracing for lateral stability

- Test arm deflection under specified loads

- Install safety stops and backstops

Timeline: 3-5 days for 20-30 bays

Dubai-Specific Installation Challenges

Climate Considerations

Temperature Management:

- Schedule installation during cooler hours (6am-11am, 4pm-8pm)

- Account for metal expansion in extreme heat

- Allow thermal adjustment time before final tightening

- Protect workers from heat stress

- Store materials in shaded areas

Dust and Sand:

- Daily cleaning of installation areas

- Protection of mechanical components during storage

- Thorough cleaning of anchor holes before installation

- Regular equipment maintenance during installation

- Dust suppression measures as needed

Free Zone Requirements

JAFZA Installation Protocols:

- Enhanced safety documentation

- Customs authority coordination

- Port authority notification for deliveries

- Stricter structural certifications

- Additional insurance requirements

Dubai Industrial City:

- Municipality representative inspections

- Coordination with neighboring facilities

- Access scheduling during operating hours

- Noise restriction compliance

- Waste disposal protocols

Access and Logistics

Urban Warehouse Challenges:

- Limited delivery windows in commercial areas

- Restricted parking and material staging

- Building access coordination

- Elevator/lift requirements for materials

- Neighbor impact minimization

Traffic and Transportation:

- Dubai traffic patterns affecting schedules

- Toll gate fees and routing optimization

- Material delivery sequencing

- Peak hour avoidance strategies

- Alternative route planning

Quality Control and Safety

Installation Quality Standards

Dimensional Tolerances:

- Vertical plumb: ±3mm per 10 meters

- Beam levelness: ±2mm per 3 meters

- Diagonal measurements: Within 5mm of square

- Base plate positioning: ±5mm from marked location

- Anchor bolt protrusion: 3-5 thread engagement

Connection Verification:

- All beam safety locks installed and engaged

- Anchor bolts torqued to specification

- Bracing connections complete and tight

- No gaps between connecting components

- Welds (if any) meet quality standards

Safety Protocols During Installation

Worker Safety Requirements:

- Hard hats mandatory (ANSI/CE certified)

- Safety harnesses for elevated work

- Steel-toe safety boots

- Cut-resistant gloves

- High-visibility vests

- Eye protection for drilling operations

Site Safety Management:

- Restricted access to installation zones

- Clear safety perimeter marking

- Adequate lighting for all work areas

- First aid equipment readily available

- Emergency contact procedures established

- Daily safety briefings for crews

Load Testing Procedures

Testing Requirements:

- Progressive loading to rated capacity

- Visual inspection during loading

- Deflection measurement at maximum load

- Duration testing (typically 24 hours at full load)

- Documentation with photographs

- Professional engineer certification

Test Load Applications:

- Water-filled containers for controlled weight

- Test pallets with measured materials

- Gradual loading in 25% increments

- Monitoring of deflection and stress

- Unloading verification of recovery

Post-Installation Certification

Documentation Requirements

Installation Completion Package:

- As-built layout drawings

- Installation certificate with date and installer details

- Load testing results and certifications

- Professional engineer approval stamp

- Photographic documentation of key stages

- Warranty documentation

- Operation and maintenance manual

Regulatory Submissions:

- Dubai Municipality final inspection request

- Civil Defense clearance confirmation

- Occupancy certificate updates

- Insurance policy documentation updates

- Building management notification

Training and Handover

Operator Training:

- Load capacity education and compliance

- Proper loading/unloading techniques

- Safety device operation and inspection

- Damage identification and reporting

- Emergency procedures

- Documentation requirements

Management Briefing:

- System capabilities and limitations

- Maintenance schedule requirements

- Inspection protocols

- Modification procedures

- Warranty terms and conditions

- Supplier contact information

Maintenance and Inspection

Initial Post-Installation Period

First Month Checks:

- Week 1: Visual inspection of all connections

- Week 2: Re-torque anchor bolts if required

- Week 3: Check for any settling or movement

- Week 4: Comprehensive inspection and adjustment

Three-Month Review:

- Detailed structural inspection

- Load capacity verification

- Connection integrity check

- Floor anchor assessment

- Documentation update

Ongoing Maintenance Schedule

Monthly Inspections:

- Visual damage assessment

- Connection security verification

- Load distribution review

- Safety device functionality

- Cleanliness and organization

Quarterly Professional Inspection:

- Comprehensive structural evaluation

- Measurement verification

- Component wear assessment

- Safety compliance review

- Documentation updates

Annual Certification:

- Professional engineer inspection

- Load capacity re-certification

- Compliance verification

- Upgrade recommendations

- Insurance documentation renewal

Cost Breakdown for Installation

Professional Installation Charges

Labor Costs by System Type:

- Selective pallet racking: AED 150-400 per position

- Heavy duty racking: AED 300-600 per position

- Drive-in systems: AED 300-700 per position

- Cantilever racking: AED 200-500 per bay

- Mezzanine floors: AED 80-200 per sqm

- Shelving systems: AED 50-200 per unit

Project-Based Pricing:

- Small installations (under 100 positions): 20-30% of equipment cost

- Medium projects (100-500 positions): 15-25% of equipment cost

- Large installations (500+ positions): 12-20% of equipment cost

Additional Installation Costs

Site Preparation:

- Floor repairs and leveling: AED 50-150 per sqm

- Anchor drilling: AED 20-40 per anchor

- Utility relocation: AED 500-5,000 per instance

- Access preparation: AED 1,000-5,000

Engineering and Certification:

- Structural engineering: AED 3,000-15,000

- Load testing: AED 2,000-8,000

- Professional certification: AED 1,500-5,000

- As-built drawings: AED 1,000-4,000

Permits and Approvals:

- Building permits: AED 500-2,000

- Civil Defense approval: AED 500-1,500

- Municipality inspections: AED 300-1,000

- Occupancy updates: AED 300-1,000

Choosing the Right Installer

Installer Qualifications

Essential Credentials:

- Licensed and insured in UAE

- Minimum 5 years Dubai installation experience

- Professional engineering partnerships

- Safety training certifications

- Manufacturer authorization (for specific systems)

- Civil Defense approval history

Quality Indicators:

- Portfolio of completed Dubai projects

- Client references and testimonials

- Safety record and incident history

- Warranty coverage terms

- After-sales support capabilities

Questions to Ask Installers

Project Planning:

- What is your project timeline estimate?

- How do you handle permit processing?

- What site preparation is required?

- How do you manage disruptions to operations?

- What safety protocols do you follow?

Technical Capabilities:

- What installation standards do you follow?

- How do you ensure quality control?

- What testing procedures do you use?

- How do you handle Dubai Municipality requirements?

- What warranty do you provide on installation?

Commercial Terms:

- What is included in your installation quote?

- Are permits and engineering included?

- What payment terms do you offer?

- How do you handle change orders?

- What post-installation support is provided?

Ensuring Installation Success

Professional installation of storage racks in Dubai requires comprehensive planning, skilled execution, and rigorous quality control. Whether installing basic shelving or sophisticated automated systems, proper installation ensures safety, regulatory compliance, and optimal long-term performance.

Working with experienced Dubai installers who understand local regulations, climate challenges, and industry best practices ensures your storage rack investment delivers maximum value. From initial planning through final certification, professional installation protects your investment while creating safe, efficient storage infrastructure that supports your business operations for years to come.

Success lies in selecting qualified installers, maintaining clear communication throughout the process, ensuring comprehensive documentation, and establishing proper maintenance protocols from day one. With proper installation and care, storage racks provide decades of reliable service in Dubai's demanding commercial environment.