Designing the project consisted of a pile of paper, a few drawings, and a lot of guesswork. Today, the people who price, sequence, and prepare the work do so much more cleanly. This shift isn't just about replacing wallets with tablets. iItsssabout changing the way decisions are made - earlier, faster, and with better evidence. This single change reduces rework, waste and gives project teams breathing room.

View the work before you start

If it's possible to execute the plan virtually and extract the quantities automatically, obvious errors can be detected before the first bricks are laid. You know what? This means fewer last-minute changes, orders, and fewer nights spent re-estimating work. Early visualization helps everyone – from site foremen to procurement – visualize the same result. Like, the result: fewer surprises and a smoother handover.

How CAD services are transforming the design-build delivery process

Digital drawing kits are not just beautiful images. Information carriers. And oh yeah, when whenhics are organized so that construction estimators' information can be reused, delivery to the field teams is accurate. Guess, Contractors can perform accurate start-ups, schedule shifts, and integrate drawings with equipment lists. This makes the transition from design to construction a predictable process rather than a leap of faith.

Collaboration that actually shortens timelines

Teams win when communication happens at the right time and in the right form. Tools that allow designers, estimators, and field teams to annotate the same model—and see each other's changes—reduce duplication. Simple rules help:

Share your single source of truth for drawings, specifications, and schedules.

Give field teams focused, lightweight perspectives; They don't need the full model to implement.

Direct questions to the appropriate person, not the entire project list.

This prevents the "who but what?" The game seems to keep progressing.

Automation that,e respects craftsmanship

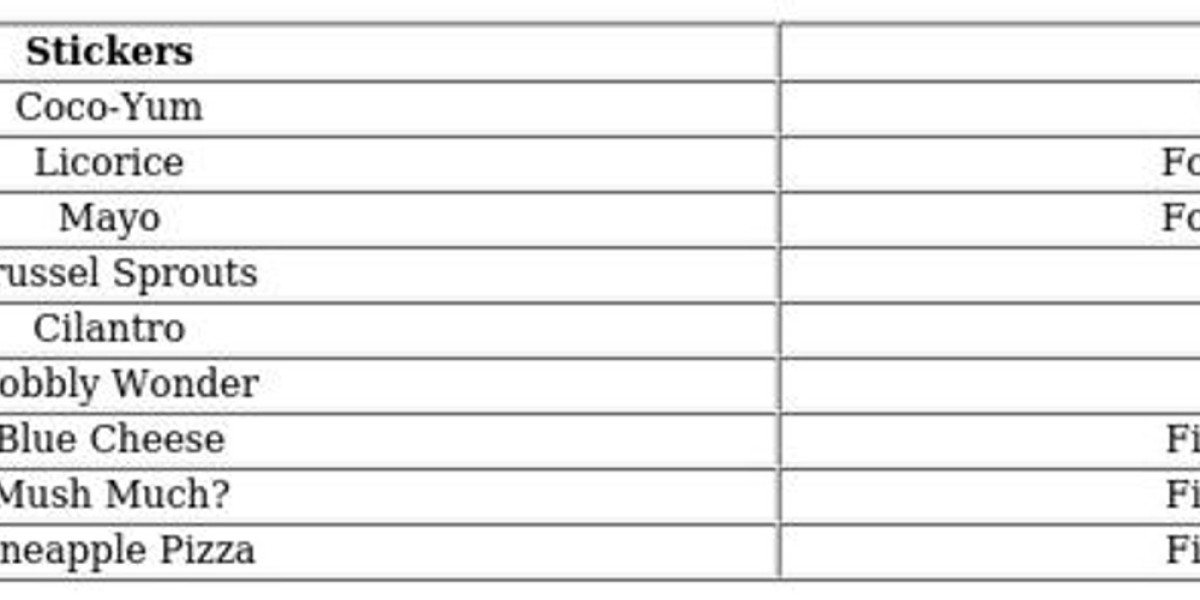

Automation can handle repetitive and time-consuming CAD Services tasks without removing human judgment. Examples that work well:

Automatic quantity extraction from structured drawings.

Rule-based conflict reports indicate potential deployment conflicts.

Template-based cost libraries that update as market prices change.

These features free, free up time and free up experienced employees to focus on micro-decisions—those that still require a human touch.

Like, Measuring real impact: schedule, cost, and flexibility

Technology is only useful if it improves measurable outcomes. Teams using modern practices typically see improvements in three areas:

Stick to your schedule, have fewer overdue tasks, and less idle time.

Cost predictability – smaller, smaller overruns and cleaner budgets.

Clearer contingency plans and better response time when something goes wrong.

Collecting simple metrics—days late, number of change orders, percentage of tasks completed on time—can give you a quick overview of whether your workflow is improving.

Increase your success with construction estimating services

When small teams standardize good estimating habits, they become repeatable across projects of different sizes. Standardized, cost libraries, clear Construction Estimating Services naming conventions for assemblies, and a concise approval process for estimates allow you to scale without losing accuracy. The reward appears in a bunch of ways:

Deliver offers quickly without sacrificing detail.

Seriously, Clear audit trails that explain the derivation of numbers.

And oh yeah, Easier setup for new estimators and managers.

Read More: What is Elemental Cost Analysis?

Standardization does not mean rigidity. This means using clear models that allow room for judgment when it matters.

Final thoughts

Practical progress in project design comes from combining craftsmanship with better tools, not chasing the latest buzzword. You know what? Change is best when it's INCREMENTAL: small improvements in organizing drawings, calculating quantities, or asking questions lead to big gains. Teams that embrace more transparent delivery processes, simple automation, and measurable results put themselves in a position to deliver on time and on budget more often. And oh yeah, Technology exists to support his goal. The hard but rewarding part is hanging the daily habits that make projects predictable and satisfying.