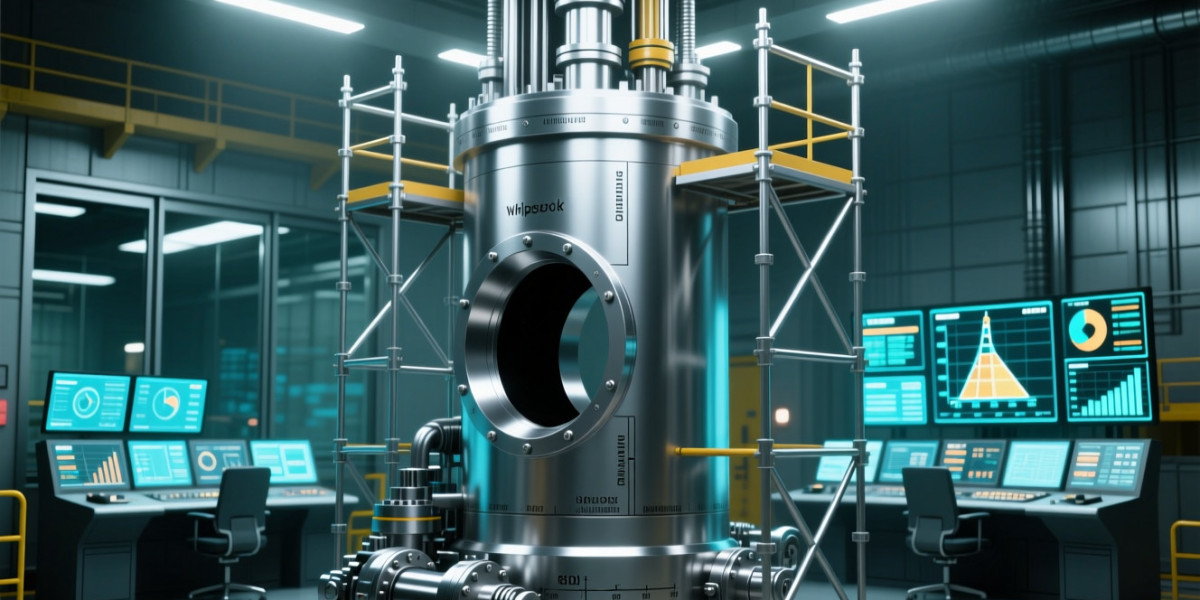

In the oil and gas industry, achieving precision and efficiency in drilling operations is critical. One of the most trusted solutions for sidetracking and directional drilling is the Eastman Whipstock, a proven tool designed for challenging wellbore environments. With decades of field success, Eastman Whipstock systems provide a reliable way to create new well paths, extend production, and maximize recovery from existing wells.

What is Eastman Whipstock?

The Eastman Whipstock is a specialized tool used in cased hole sidetracking operations. Its main purpose is to deflect the drilling bit at a predetermined angle, enabling the creation of a new borehole trajectory from an existing well. This makes it an essential technology for operators who need to:

- Bypass stuck pipe or fish in the hole.

- Re-enter wells to access untapped zones.

- Improve recovery by drilling laterals.

- Optimize reservoir contact in complex drilling environments.

By combining robust engineering with practical field application, Eastman Whipstock delivers precision and dependability in even the most demanding conditions.

Key Advantages of Eastman Whipstock Technology

- Accurate Wellbore Deflection

The whipstock design ensures the drill bit is guided in the exact direction needed, minimizing risks of deviation. - Time and Cost Savings

Sidetracking with a whipstock eliminates the need for drilling a new well from surface, reducing overall expenses. - Enhanced Reservoir Access

Operators can target bypassed or marginal zones, extending the productive life of the well. - Versatile Applications

Suitable for both open hole and cased hole environments, Eastman Whipstock systems offer flexibility in deployment. - Proven Reliability

With a long track record in the industry, Eastman Whipstock has earned a reputation for consistent and predictable performance.

Eastman Whipstock in Cased Hole Operations

In cased hole sidetracking, whipstock systems are set inside the existing casing. A carefully engineered anchor system holds the whipstock in place while the milling tool cuts a window in the casing. Once the window is created, drilling proceeds in the new trajectory.

This process is particularly valuable when:

- The original wellbore encounters obstructions.

- Re-entry is required for deeper reservoir targets.

- Operators aim to improve drainage and increase production.

Why Choose Eastman Whipstock with ProGrynd?

At ProGrynd, we understand the importance of reliable and efficient directional drilling tools. Our cased hole whipstock services, including the Eastman Whipstock system, are designed to meet modern drilling challenges with precision and efficiency. By choosing ProGrynd, you gain access to:

- Industry-leading whipstock technology.

- Expert field support and technical guidance.

- Tailored solutions for both conventional and unconventional reservoirs.

- Proven track record of successful sidetracking operations.

Conclusion

The Eastman Whipstock remains a cornerstone of sidetracking and directional drilling technology. Its ability to provide precision, reliability, and cost-effectiveness makes it a go-to choice for operators worldwide. Whether bypassing obstructions, accessing new zones, or extending well life, Eastman Whipstock ensures successful outcomes in even the most challenging drilling environments.

For more information on our cased hole whipstock solutions, visit: http://progrynd.com/casedhole-whipstock/