The Aircraft Engine Borescope Inspection Market is experiencing significant growth, driven by the aviation industry's unwavering focus on safety, efficiency, and cost-effectiveness. Borescopes, with their ability to provide non-destructive visual inspections of engine internals, are becoming indispensable tools for maintenance and repair. This analysis delves into the market's current state, key drivers, challenges, and prospects.

Market Overview and Current Scenario:

Aircraft Engine Borescope Inspection involves using optical devices to visually inspect the internal components of aircraft engines without requiring disassembly. This technique allows for the early detection of defects, preventing costly repairs and ensuring flight safety.

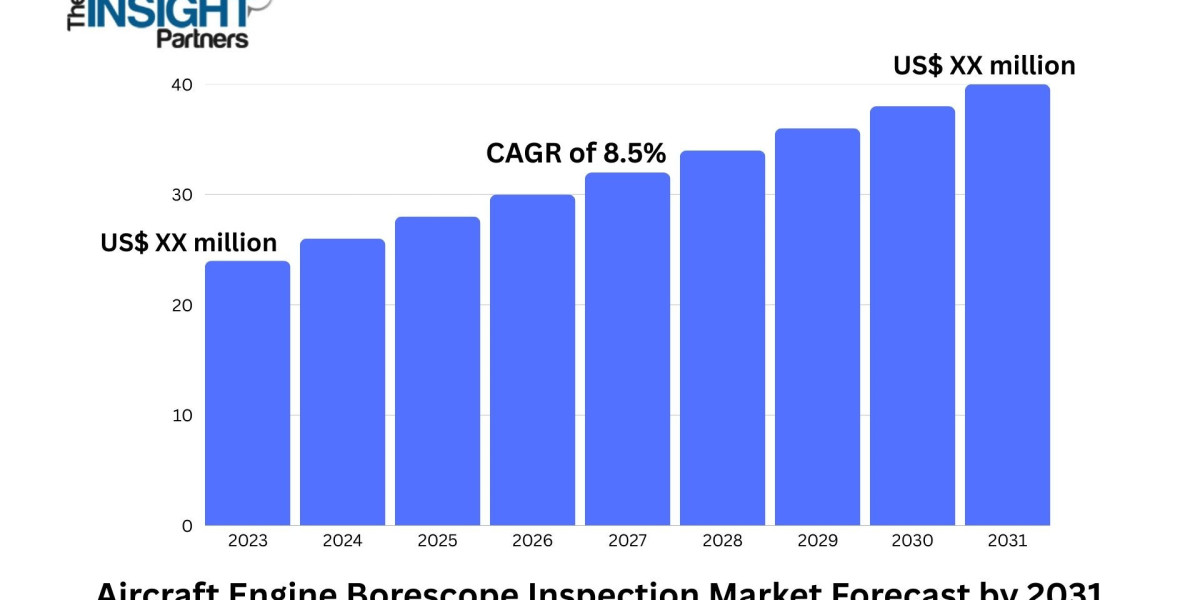

The market is witnessing robust growth, fueled by the increasing demand for preventative maintenance and the adoption of advanced inspection technologies. The Aircraft Engine Borescope Inspection market is projected to grow at a CAGR of 8.5% from 2025 to 2031. This substantial growth is supported by the rising number of aircraft in service and the increasing complexity of modern engines.

Key Growth Drivers:

- Emphasis on Preventative Maintenance: Airlines and maintenance providers are increasingly adopting preventative maintenance strategies to minimize downtime and reduce costs.

- Stringent Safety Regulations: Aviation safety regulations mandate regular inspections of aircraft engines, driving the demand for borescope inspection services.

- Technological Advancements: Advancements in borescope technology, such as high-resolution imaging, 3D modeling, and AI-powered defect detection, are enhancing inspection capabilities.

- Aging Aircraft Fleet: The aging aircraft fleet requires more frequent inspections to ensure continued airworthiness, boosting the demand for borescope services.

- Cost-Effectiveness: Borescope inspections are cost-effective compared to engine disassembly, making them a preferred maintenance technique.

- Increased MRO Activities: The growth of the maintenance, repair, and overhaul (MRO) sector is driving the demand for borescope inspection services.

Market Challenges and Opportunities:

Despite its strong growth potential, the Aircraft Engine Borescope Inspection Market faces certain challenges:

- Skilled Labor Shortage: Performing accurate borescope inspections requires skilled technicians with specialized training and experience.

- Technological Complexity: Operating and interpreting data from advanced borescopes requires technical expertise.

- Data Management and Analysis: Managing and analyzing the large volumes of inspection data generated by borescopes can be challenging.

- High Equipment Costs: Advanced borescopes and inspection systems can be expensive, limiting their adoption by smaller MRO providers.

- Regulatory Compliance: Ensuring compliance with evolving aviation safety regulations requires continuous updates and training.

Future Outlook and Market Trends:

The future of the Aircraft Engine Borescope Inspection Market is characterized by continuous innovation and adaptation. Key trends shaping the market include:

- AI-Powered Defect Detection: The integration of AI and machine learning algorithms is enabling automated defect detection and analysis, improving inspection accuracy and efficiency.

- Remote Inspection Capabilities: The development of remote inspection technologies is enabling real-time collaboration and expert consultation, reducing travel time and costs.

- 3D Modeling and Virtual Reality: 3D modeling and virtual reality technologies are enhancing the visualization and analysis of inspection data, improving decision-making.

- Integration with Digital Twins: The integration of borescope inspection data with digital twins of aircraft engines is enabling predictive maintenance and proactive problem-solving.

- Wearable Technology: The use of wearable technology is enabling hands-free operation and real-time data access for technicians.

Conclusion

The Aircraft Engine Borescope Inspection Market is poised for substantial growth, driven by the aviation industry's focus on safety and efficiency. The projected CAGR of 8.5% from 2025 to 2031 underscores the market's strong potential and its critical role in ensuring the airworthiness of aircraft engines.